|

DISMOUNTING OF ENGINE 1) Clean engine before dismounting.

2) Screw off exhaust socket.

Tool:hex. socket screw key 6 mm

Dismount cylinder cowl and fan cowl with rewind starter.

Tool: socket wrench 10/13 mm

Screw off carburetor socket

Tool: hex. socket screw key 6 mm

Fix crankshaft to top dead center through the impulse connection.

Tool: crankshaft fixation bolt 876 640

Unscrew starting pulley,

Tool: socket wrench 10 mm

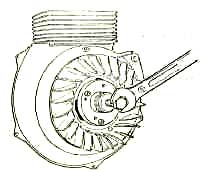

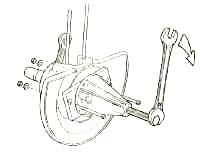

Fix puller ring on the magneto housing with 3 hex. screws

M8 x 25.

Tools: puller ring 876 655

hex socket screw key 5 mm

Unscrew crankshaft nut, mag. side

Tool: Socket wrench 27 mm with extension (or torque wrench)

Place protection mushroom on crankshaft and screw puller into puller

ring, then pull off the magneto housing (see ill. no.

Tools: Protection cap 876 557, puller ring 876 655 puller for magneto

housing 876 065 fork wrench or socket wrench 22

277 Rotax - Rotax 277

Engine Manual

Dismount ignition coil

Tools:

Socket wrench, screwdriver

Mark armature plate position to crankcase for re-assembly. Screw off

armature plate, remove cable grommet and pull through wiring harness.

Tools:

Hexagon socket screw key 4 mm screwdriver

Unscrew cylinder head nuts

Tool: Socket wrench 13 mm

13) Take off cylinder head, cylinder head gasket, cylinder and cylinder

base gasket.

14) Cover opening in crankcase with a clean cloth.

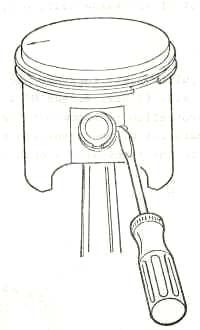

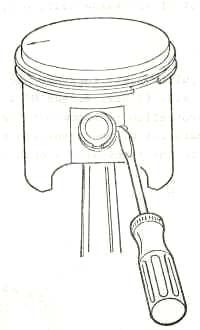

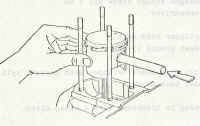

15) Remove piston pin circlips (see ill. no. 2)

Tool:

Small screwdriver, shaped as shown on ill. no. 2.

277 Rotax - Rotax 277

Engine Manual

Push piston pin out by hand.

Tool:

Suitable punch for piston pin.

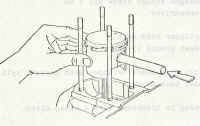

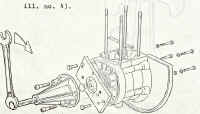

Attention:

When pushing out the piston pin, the piston must be firmly held by hand

to prevent bending of the connecting rod (see ill. no. 3).

hand

to prevent bending of the connecting rod (see ill. no. 3).

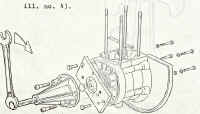

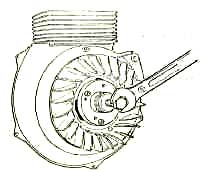

Dismount, crankcase and remove crankshaft. Remove the 5 hex. screws with

socket wrench i3 mm.

Push crankshaft out of crankcase half, p.t.o. side, with a puller.

Procedure:

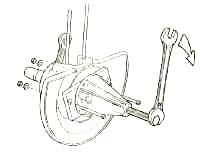

Screw puller and puller plate together and fix them on crankcase, p.t.o.

side (2 hex. screws M8 x 25). p.t.o.

side (2 hex. screws M8 x 25).

Attention:

Use

protection mushroom 876 552.

Then push crankshaft out of the crankcase by turning the puller screw

to the right with wrench 22 mm (see ill. no. 4).

277 Rotax - Rotax 277 Engine Manual

Take crankcase gaskets carefully off.

After removing the crankshaft from the crankcase, p.t.o. side, remove

puller with plate. The puller itself need not be screwed off the plate.

The puller with plate is then placed on crank- case, mag. side, and is

fixed by 2 screws M8 x 100. Use protection mushroom 876 557.

ATTENTION:

To avoid damage to the crankcase sealing surface, shims

have to be used by all means and the nuts have to be tightened by hand

(see ill. no. 5).

Tools:

puller plate 876 705

puller assy. 876 296

2 cyl. screws M8 x 100

2 washers 8.4 mm

2 hex. nuts M8

protection mushroom 876 552 protection mushroom 876 557

277 Rotax - Rotax 277

Engine Manual

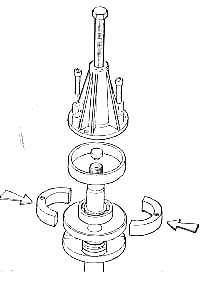

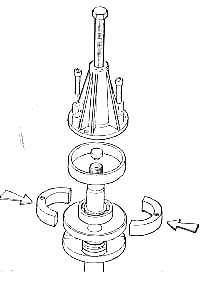

Removing of ball bearing from crankshaft

see ill. #6.

Put ring halves for bearing 6306 over ball bearing.

Put outer ring over ring halves 276 020.

Use protection mushroom 876 552 or 876 557.

Fix puller by 2 cyl. screws M8 x 40 to the ring halves. Pull off ball

bearing by burning the puller screw to the right.

Repeat procedure for ball bearing

6206 with ring halves 977 470.

|