|

Clean the parts dismounted and check whether they can be used again. Checking the crankshaft

First check whether the 2 centering holes on the crank- shaft are in

order. If damaged, rework them. Place crankshaft between centers of a lathe or similar device and check

crankshaft for centricity.

Maximum allowable out of round 0.08 mm (0.003 in.) measured with a dial gauge on the

bearing seats. If out of round exceeds 0.08 mm (0.0103 in.) the crankshaft

has to be realigned. This kind of job should be done by experts only.

In case of excessive radial clearance of the con rod

big end bearing or if the crankshaft is in any other way defective, the

crankshaft has to be replaced.

277 Rotax - Rotax 277 Engine Manual

Place radius shim 827 440 on crankshaft., p.t.o. side. Warm ball bearing 6306 to approx.

80 degrees C (180 F) and push it on

crankshaft, p.t.o. side. Push firmly to assure proper seat of the bearing.

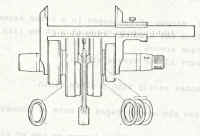

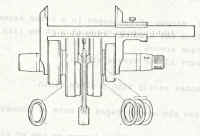

Place radius shim 827 44o and shim(s) 944 582 - 944 586 as required to the crankshaft, magneto side. Warm ball bearing

6206 to approx. 80 degrees C (180 F) and push it on crankshaft, magneto side. Push

firmly to assure proper seat of the bearing.

ATTENTION

Never clamp a crankshaft with the crankpin in a vise

trying to mount a bearing because in this case the crankshaft could be

bent and would have to be centered again.

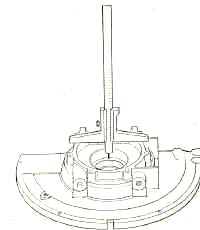

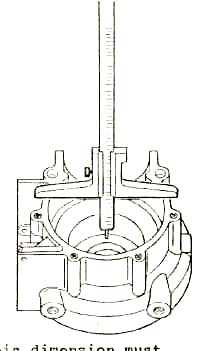

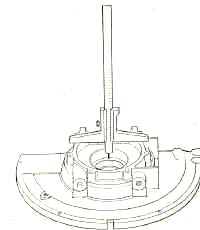

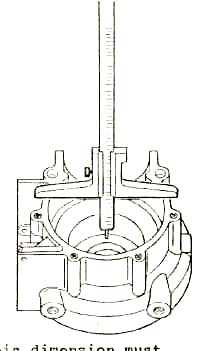

Measuring and adjusting of axial bearing play

The crankshaft installed must have an

axial bearing play

of 0.2 -0.5 mm ( 0.008 -0.020 in.). To measure this, the crankshaft and the 2 crankcase halves have to be measured with a

slide gauge (see ill. no.8 and 9).

277 Rotax - Rotax 277 Engine Manual

Crankcase half, p.t.o. side

distance between sealing surface and bearing seat 10 -

The 2 dimensions have to be added. This dimension must be balanced by

shims on crankshaft, magneto side Ull. no. 10).

Ill. no.

By adding the crankcase gasket at assembly of crankcase halves, the

thickness of the gasket gives the required axial play of crankshaft between the bearings.

ATTENTION:

The 2 main bearings have to be mounted so that the cage backs show

towards the oil seals. When adding or removing shims (if necessary), the

bearing, mag. side, has to be pulled off the crankshaft, then be warmed up

again and mounted as per ill. no. 7.

|