277 Rotax - Rotax 277 Engine Manual

To avoid damage to the crankshaft resp. to the bearing, the puller

assy. for ball bearing 6305.has to be used (see removing of bearing, ill.

no. 6).

MOUNTING OF CRANKSHAFT

Warm crankcase, magneto side, up to approx. 800C

( 180 degrees F) Press oil seal 230 425 with mounting jig till to the stop.

Press

crankcase ring 960 765 in with mounting jig.

Fill groove between oil seal

lips with high temperature bearing grease and mount crankshaft.

Place

crankcase gasket.

Mount oil seal 850 050 and aluminum crankcase ring 827 820 in

crankcase, p.t.o. side.

Mount crankcase half.

Tool: Rubber hammer (plastic hammer).

Tighten hex. screws of crankcase in a cross sequence (starting from the middle) with 18

-24 Nm (160-210 in.lbs)

Tools:

Torque wrench insert 13 for torque wrench

Close crankcase cavity with a clean cloth.

Insert piston pin needle cages in bore of connecting rod

Warm up piston to 40 - 50 degrees c

(arrow on top of piston must show

towards exhaust).

Insert guide pin for piston pin through the piston hole and connecting

rod bore. Take care not to damage the needle bearing.

Coat piston pin with oil, place it on guide pin and insert it

into piston hole. All punch impact must be absorbed by your hand to avoid

bending of the rod (arrow on piston crown must show towards exhaust).

Secure pist0n pin with circlips. ATTENTION:

The circlips must engage in the grooves of the piston. Use new

circlips. Insert circlip, in such a way that open ends are not over the

rectangular slot of the piston, as otherwise the circlip would have to be turned around when

disassembling

later on.

Circlips must sit tightly in the groove.

Tool: Screwdriver shaped as shown on ill. no. 2

Mount cylinder base gasket.

Attention: This gasket is

not symmetrical. Place it in the correct position. Take care of the transfer recesses in the

crankcase.

Lubricate piston and bring piston rings in correct position (securing

pin between ends of piston ring).

Press piston rings into the grooves and mount oiled cylinder over the

piston.

Mount cylinder head gasket and cylinder head. Tighten hex. nuts M8 at

18 - 24 Nn (160 - 210 in. lbs) in a cross sequence,

Tools: Torque wrench insert 13 nun for torque wrench.

Mount armature plate so that marks on armature plate and crankcase

correspond.

Fix armature plate with allen head screws and insert cable grommet.

Tool: Hex. socket screw key 4 mm

Mount Woodruff key on crankshaft taper.

Fix piston to top dead center by inserting a crankshaft fixation bolt

through the impulse nipple.

277 Rotax - Rotax 277 Engine Manual

Clean crankshaft taper and taper in inagneto housing with degreasing

agent (e.g. trichloroethylene).

Coat crankshaft taper with LOCTITE 242 blue (899 786)

Mount magneto housing with assembled fan on the

crank shaft.

Attention:

Before mounting magneto housing with fan on the crank- shaft, take care

that the ignition unit and especially the magnets are clean and free of

foreign material.

Magneto housing nut

Secure thread of hex. nut M18 x 1.5 with LOCTITE 242 blue,

899 786, and tighten hex. nut with torque 90 Nm (800

in. lbs).

Tools:

Torque wrench insert 27 mm for torque wrench

IGNITION ADJUSTMENT

Ignition timing 190 ( 2.03 - 2.53 mm

or 0.08 - 0.10 in before top dead center)

Procedure

To adjust the contact breaker gap., the piston has to be placed to top

dead center. Adjust contact breaker gap to 0.4 mm (0.016 in.). To do so,

loosen the fixation screws of the contact breaker set and push the

contacts with a screwdriver until the gap is 0.4 mm (0.016 in.). This

distance has to be checked with a feeler gauge.

Then turn crankshaft until the contact breaker cam makes the contact

lever lift (check with buzzer or check lamp); connection to shorting cable

and to mass.

Now the mark on crankcase has to correspond with the mark @ on the fan.

If the marks don't correspond, the contact breaker gap can vary between

0.35 and 0.45 MM (o.o14 -0.018 in.) to achieve correspondence.

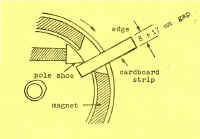

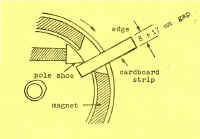

BREAK-AWAY GAP

When correct timing is achieved, check pole shoe break- away gap.' The

gap must be within 8 to 17 mm or 0.3 to 0.67 in. (see illustration) when the mark on the flywheel

corresponds with the mark on fan housing.

If

the break-away gap is out of tolerance, the flywheel may have turned on

the crankshaft. Remove flywheel and inspect taper and key. Repair if

necessary. If

the break-away gap is out of tolerance, the flywheel may have turned on

the crankshaft. Remove flywheel and inspect taper and key. Repair if

necessary.

Mount ignition coil

Tools: Socket wrench 8 nun screwdriver

Screw on starting pulley

Tool: Socket wrench 10 mm

Mount fan cowl and cylinder cowl.

Tool: Socket wrench 10 and

13

mm

Mount carburetor socket with gasket

Tool: hex. socket screw key 6 mm 19 sp,

Screw on exhaust socket with gaskets and air guide.

Tool: hex. socket

screw key 6 mm.

Remove crankshaft fixation bolt.

|