| A thermocouple is a device formed by the junction

between two special dissimilar metals which transforms heat energy into

electrical energy. Aviation EGT and some CHT systems use thermocouples,

lead wires composed of the same two dissimilar metals, and an gauge

which is basically a millivolt meter.

Most aviation EGT and CHT Systems are based around three

types or thermocouples. The most common type K, is used on most EGT

systems. It uses chromel and alumel wires in the element and lead. |

| Many CHT Systems use a type J system or iron

and constantan metals.

Thermocouples used in aviation are simple to

troubleshoot with a good quality digital multi-meter The meter should be

fitted with alligator clips on the test leads. |

Integrity check: Inspect the entire system

for loose connections, broken wires or connectors, or mismatched

color codes.

Color codes must match throughout the entire system

from the indicator to the probe, including the lead wires.

Resistance check: Care should be taken

to be sure the meter and or the probe have been un-hooked before

checking for loop resistance. A grounded type K probe Will normally show

from O.6 to 1.0 ohms. The same goes for type E or red and brown probes.

Type J CHT probes will show a reading of about 0.24 ohms. NOTE: Many CHT

Systems do not operate on the thermocouple principle. A CHT probe with

no color codes or only one wire works on resistance changes as opposed

to millivolt output. Consult the manufacturer for details.

CAUTION - voltage from a multi-meter can damage an EGT or CHT indicator.

Millivolt output check, (EGT ONLY): Using a propane

torch, carefully heat the tip of the probe until it glows cherry red. At

this point, the probe should put out between 20 and 30 millivolts.

CAUTION - Always wear gloves and have a fire extinguisher handy when

using an open flame.

If your probe passes these tests, check with the

manufacturer of your indicator for calibration or repair information.

|

EGT System Troubleshooting

Guide

|

| SYMPTOM |

POSSIBLE CAUSE |

SOLUTION |

SEE NOTE |

| No Indication |

Open Thermocouple |

Check Probe: Heat Resistance |

1 |

| Shorted or Open Circuit |

Check Continuity |

2 |

| C/A Probe on C/C System |

Check Color Codes |

3 |

| Bad Pot |

Repair

or Replace |

4 |

| Friction in Movement |

Repair

or Replace |

4 |

Low Indication

at Peak |

| C/A Probe on C/C System |

Check Color Codes |

3 |

| Probe - High Resistance |

Check Probe Heat or Resistance |

1 |

| High Indication |

| C/C Probe on C/A System |

Check Color Codes |

3 |

| Induced EMF Through Lead |

Check Harness Route |

5 |

| Erratic Reading |

Bad Potentiometer or

Friction in Movement |

Repair

or Replace |

4 |

T/C Wire Insulation

Worn at Radiator |

Check T/C Resistance While Wiggling Wire |

1 |

| Erratic Reading

at Altitude |

Lead Chafed-Grounding |

Check Continuity to Ground While in Fit |

2 |

| Indicator Change

when Tapped |

Faulty gauge |

Repair

or Replace |

4 |

| No Indicator

at Run-Up |

Indicator Begins at 1200 F

Not All Engines Reach

1200 F at Run-Up |

System Normal |

|

Indicator Works

on Bench,

Not in Flight |

Probe, leads |

Repair

or Replace |

4 |

|

|

1. The best way to troubleshoot EGT

probes is to check the loop resistance through the probe at room

temperature. Use a good quality multi-meter fitted with alligator clips

on the test leads.

CAUTION: Voltage from a multi-meter can damage an

EGT gauge.

Care should be taken to be sure the probe has been

disconnected from the system before checking for loop resistance. A

grounded red/yellow or red/brown probe will normally show from 0.6 to

1.0 ohms resistance.

To check millivolt output, remove probe from

aircraft. Carefully heat the tip of the probe element with a propane

torch until it just begins to glow dark cherry red. At this point, the

probe should put out from 33 to 36 millivolts (1500 to 1650 degrees F)

for red/yellow, or 61 to 67 millivolts (1500 to 1650 degrees F) for

red/brown.

CAUTION: Always wear gloves and have a fire extinguisher

handy when using an open flame. |

| 2. To check continuity of an EGT extension lead, first

inspect entire length of wire for chafing or broken insulation. Inspect

terminals for loose crimps or connections. With indicator and probe

disconnected, check to be sure that there is no continuity from red to

yellow or from red or yellow to thermocouple housing. Next, clip red to

yellow at either end and check for continuity at opposite end through

the entire lead. |

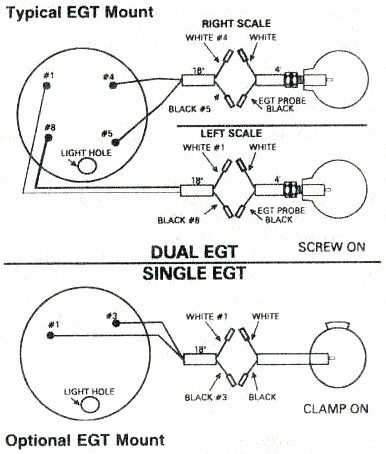

| 3. The latest Rotax engines use a bayonet style

probe, and the exhaust manifold has been manufactured for probe

placement at the correct distance from the piston.

Older units used a clamp on style probe which has to

be installed at the proper distance from the piston, has to be

centered on the manifold and in the exhaust pipe. It cannot be

allowed to touch the inside of the exhaust manifold pipe, it must

sit in the center of the exhaust gasses. |

4. Calibration on EGT or CHT indicators

MUST be checked against spark plug colour.

See How to read your spark plugs. |

| 5. To prevent indicator error due to induced EMF, the

EGT or CHT extension lead wires must not be bundled up or routed with

any high current bearing wires such as alternator, avionics, lighting,

heaters etc. |