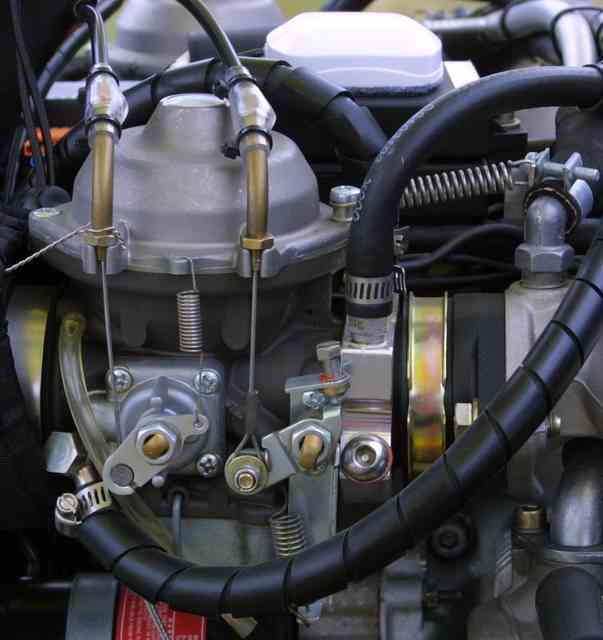

The 912 series

of engines use an altitude compensating Bing carburetor. These are very

reliable, and literally trouble free if properly set up and maintained. The 912 series

of engines use an altitude compensating Bing carburetor. These are very

reliable, and literally trouble free if properly set up and maintained.

To properly set them up requires several tools.

A feeler gauge.

A double vacuum gauge.

Two 9 mm open end wrenches to adjust the M5 nuts on the throttle cables.

The following are the recommended steps to adjust the carbs.

IMPORTANT: make sure cables are not effected by ANY engine movement,

and that they move FREELY back and forth with no stickiness.

- First step is to allow the engine to come up to operating

temperature, this should be in the 200 degrees F water temperature, and 1200

EGT.

- Make sure that the engine has been loaded with a properly adjusted

propeller that limits the rpm tied down on the ground to 5600 rpm.

- Make sure that both throttle cables are allowing full opening of the

throttle valve. This can be done visually with the engine turned off and

full power applied.

- With the engine turned off bring the throttle back to an idle.

Adjust the idle screws back until the carb actuating arm is

against the carb body.

- Adjust the idle screws in until they touch the actuating arms, now

adjust them each an additional 1 1/2 turns.

- Gently adjust the air mixture screws in all the way and then back

them out

1 1/2 turns.

- Have someone start applying throttle very slowly, adjust the cables at

the fittings so both cables begin opening the throttle arms at the same time.

- Start the engine and adjust the idle screws equally until

you obtain 2,000 rpm for an idle speed.

- This procedure will normally synchronize the carbs at an idle.

- Now with the engine still turned off have someone advance the

throttle slowly, adjust the throttle cables so that they are both taunt,

and so that both throttles start opening at exactly the same time.

- Once you have done this bring the throttle to half throttle and

measure the distance between the throttle activation arm and the carb

body, they should be the same.

- Advance to full throttle, both throttle arms should be in the full

open position.

If there is a problem with the synchronization of the cables it can

usually be traced to movement in the outer throttle casing. That is when you are

applying throttle instead of it moving the cable the outer casing is

flexing or bending.

traced to movement in the outer throttle casing. That is when you are

applying throttle instead of it moving the cable the outer casing is

flexing or bending.

If this is the case you MUST secure, or route the

cable so that all of the throttle movement is directed to the throttle

arm.

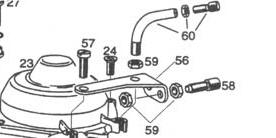

In the standard configuration you would use #60 and & #58 to adjust

the throttle and choke set up on a Rotax 912 equipped with Bing

carburetors.

Using a vacuum gauge

First perform

a manual synchronization adjusting the Bowden cables so there is full

travel from full open to full closed of the throttle valve arm, as

described above.

Then

remove the compensator tube and install the gauges. Rotax provides a small

plug screw, left of the idle mixture control screw on the carburetor to

connect the hoses from the vacuum gauges.

However, you still have to

remove the compensator tube and plug the passage way before the carbs can

be synchronized.

With this in mind, it's really easier to just connect the

vacuum hoses where you disconnected the compensator tube.

After you adjust the carbs, the vacuum

gauges should read the same at all engine settings.

Remember, it's the length

and the tightness of the cables that adjusts the carb synchronization. When you're adjusting

them, you're simply lengthening or shortening a cable, and making each

throttle valve arm move the same distance at the same time.

Click here for video showing how to properly set carbs. |

The 912 series

of engines use an altitude compensating Bing carburetor. These are very

reliable, and literally trouble free if properly set up and maintained.

The 912 series

of engines use an altitude compensating Bing carburetor. These are very

reliable, and literally trouble free if properly set up and maintained.

traced to movement in the outer throttle casing. That is when you are

applying throttle instead of it moving the cable the outer casing is

flexing or bending.

traced to movement in the outer throttle casing. That is when you are

applying throttle instead of it moving the cable the outer casing is

flexing or bending.